|

The Bartlett Peg Mill

|

The Bartlett Peg Mill did not let itself get left behind by

changing times. They still operate today, just a little

differently.

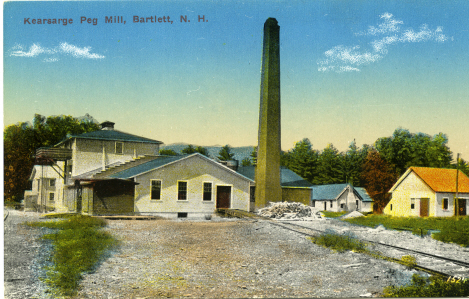

Follow this link to see what they are doing TODAY  Kearsarge Peg Mill circa 1912

Material Source Credit:

I have taken the liberty of copying this information from

Kearsarge Peg Company's web site/advertising material. The

link to this same site data is shown above and there is much

more detailed information there as well.

FEB 12, 2016-BARTLETT — No one was injured but one of the world’s most unusual manufacturers and a major part of the town’s history was destroyed Friday afternoon when a fire leveled the Kearsarge Peg Company.

Bartlett Fire Chief Pat Roberts, who said the fire was reported around 1:11 p.m. Friday by a custodian from the nearby Josiah Bartlett Elementary School, called the mill a total loss.

Three people were inside the structure at the time of the fire and they managed to exit safely. Roberts said firefighters from between Tamworth and Jackson responded to the scene, adding that water and weather were both challenges. The first, he said, had to be drafted from the Saco River and then shuttled, while the second was down-right cold, with temperatures in the low double digits that froze firefighters and water alike. While the cause and origin of the fire remain under investigation, Roberts was clear that the fire is “absolutely not” suspicious. Gene Chandler, who chairs the Bartlett Board of Selectmen and is also a state representative, called the destruction of the mill “a terrible loss for the history of the Town of Bartlett,” recalling how the mill had at one time been one of the town’s largest employers and also a supplier of saw dust to farms, like the Chandler’s. The wooden pegs — primarily from white, yellow and silver birch, although white maple and beech were occasionally employed as well, according to the company’s online history — were used “as a component of shoe manufacturing in the 19th and early 20th century, and replaced shoe nails, as a means for insuring a lasting bond between the last and sole of the shoe.” After World War II, the use of wooden pegs shifted toward industrial applications, specifically as a tumbling and finishing medium, and in 1949 when the Moore Peg. Co. of Lisbon was destroyed by fire, Kearsarge Peg stood alone in North America. Whitemountainhistory.org says that Kearsarge Peg — which was founded in Andover in 1865 and moved to Bartlett in 1878 — “remains as the last shoe peg mill in the world still using technology and machinery from the late 1800s and early 1900s,” according to officials. - See more at: http://www.unionleader.com/Fire-destroys-historic-peg-mill-in-Bartlett,-allegedly-the-last-shoe-peg-mill-still-using-machinery-from-the-1800s. Two Minute Video From WMUR TV |

Kearsarge Peg Co., Inc. is a business located in Bartlett, NH that has been in continuous operation in this location for 121 years. The company has prospered through the years on its reputation for quality products and timely delivery. The original product (hardwood shoe pegs and hardwood tumbling media) is still manufactured in the facility, and in fact, Kearsarge is the only manufacturer of this product in North America.

The principal business of the company at its inception was the manufacture of shoe pegs. Shoe pegs were long cross sectioned hardwood shapes with a point on one end, manufactured primarily from white, yellow and silver birch, although white maple and beech are occasionally employed as well. The Kearsarge Peg Co. manufactured approximately seventy-five different sizes of shoe pegs, which varied in size from 5/16 in. long by 1/18 in. wide to ¼ in. wide by 2.0 in. long . This product was used as a component of shoe manufacturing in the nineteenth and early twentieth century, and replaced shoe nails, as a means for insuring a lasting bond between the last and sole of the shoe. It was considered superior to metal nails, in that over time the wood peg would draw moisture from the ambient atmosphere and swell, forming a lock fit between these two components. Shoe manufacturing along with textiles was a major segment of the economy of New England at this time, and there were dozens of plants, which made this product in competition with Kearsarge. In its earlier years, Kearsarge exported heavily to the shoe industry in Norway, Germany, Australia and elsewhere. The use of pegs in shoe manufacturing came to an abrupt halt with the advent of the Second World War. (Exception: custom made climbing, skiing and cowboy boots). Not only did the company find that its export markets were now closed, but new developments in shoe manufacturing technology obviated the need for pegs to tie or lock the last and sole of shoes together. Lupoline, under the director of its founder Joseph Lupo of pioneered dry barrel finish or tumbling techniques in the early part of the twentieth century, with some patents dating as early as the 1920’s and 1930’s. He found that “shoe pegs” made an ideal mass finishing media for smoothing and polishing plastic parts in rotary barrel finish equipment. This technology was quickly adapted by major manufacturers such as Bausch & Lomb, Foster-Grant and the American Optical Co. and others to replace tedious manual finishing methods that involved buffing. These large manufacturers of eyeglass frame and sunglass frame components were soon utilizing hardwood pegs in bulk, by the truck load and even car load for abrasive finishing and polishing operations. This continues to be the primary use for hardwood pegs and other hardwood preform shapes that the company manufactures to this day. In the early 1980’s the company management decided that there was a need to become more involved on a technical level with the finishing industry. As a result the PEGCO Division was instituted as a marketing and technical arm to more aggressively market hardwood media for other applications. It soon became apparent that there was a need to make PEGCO a technical resource for the finishing industry. Its focus became providing technical solutions to difficult edge and surface finish problems by process development in its “process laboratory” and offering turn-key equipment and abrasive supply packages as the solutions to these problems. The company’s office and manufacturing facilities are found at the same location in Bartlett, NH. These facilities are comprised of approximately 25,000 square feet of manufacturing and warehouse space encompassed in an eleven building complex, situated on seven acres bounded by Kearsarge Street and the White Mountain National Forest.

Dave Davidson sent me this link: "You may find this one interesting as well as it has a great deal of graphical content regarding Kearsarge Peg Co.'s 19th century and early 20th century history"

Follow this link |